Overview

Cargo City by Aeroporti di Roma. Over two million tons of goods handled per month. A network of 200 direct connections served by 100 airlines. The pride of Italian airport facilities.

Requirements

Intervene on existing natural smoke and heat exhaust vents, integrating them with new devices to ensure optimal operation, considering the extremely delicate installation context.

Ensure a renewed level of safety for operators, goods, and the entire airport perimeter.

Product/Service provided

The interventions concern some sensitive extra-customs areas of the airport premises, subject to security clearance for access.

Following the site survey, our technical department verified the state of the art. The solution is completely customized:

- design of integrations to the existing system;

- production of new smoke exhaust vents;

- installation of the integrations to the system; maintenance and repair of both new and previous exhausts.

Tecnocupole Pancaldi guarantees a constant presence on site mitigating any critical situations.

The intervention plan, hypothesized and put into practice within eighteen months, produced the following results:

- Safety measures applied to 21 existing compartments;

- Creation of 17 new compartments;

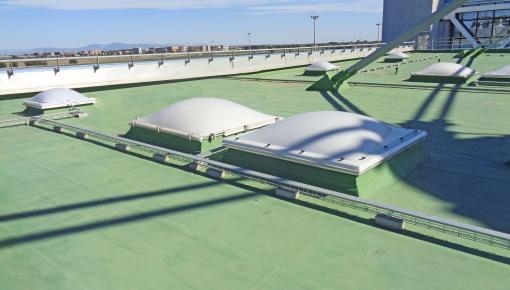

- Installation of 264 new automatic activation smoke and heat exhaust ventilators (SHEV) with polycarbonate domes and fall protection grids;

- Installation of 2,400 meters of pneumatic line to connect the new SHEVs to the control panels.

Additional Services

Testing and inspection at the end of the installation confirm the functionality and correct design of the entire work.

The operation of certified installers - who are admitted inside Cargo City - allows for a systematic verification phase without any inconvenience to the surrounding environment.

Final checks confirm the achievement of the intended objective and the planning of times and methods to be applied for subsequent periodic checks.

Results

Tecnocupole Pancaldi provides a “turnkey” option that includes supply and installation. This proposal, selected by the customer, guarantees a series of aspects that affect the final result: at the end of the work, the percentage of existing smoke exhaust ventilation systems with functional issues decreases from 75% to 0%.

Our initial briefing activity combined with a concrete verification of the existing situation - even in a complicated environment - is the basis for the creation of an excellent product. The product is high-performing in terms of materials (double-wall polycarbonate skylights), safety (each smoke exhaust ventilation system is equipped with a fall protection grid for workers on the roof) and functionality.

The installation is planned with precision and constant management of the mandatory certifications for access to the extra-customs area affected by the work.